Shell and Tube Heat Exchangers – Trusted Manufacturer in India

What is a Shell and Tube Heat Exchanger?

A

Shell and Tube Heat Exchanger is one of the most commonly used types of

heat exchangers in India. It consists of a series of tubes, one set carrying hot fluid and the other cold fluid. Heat transfer occurs between the two fluids without direct contact. This system is highly efficient, especially in

industrial cooling and heating applications.

How Shell and Tube Heat Exchangers Work?

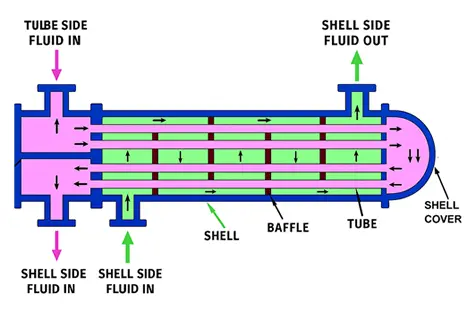

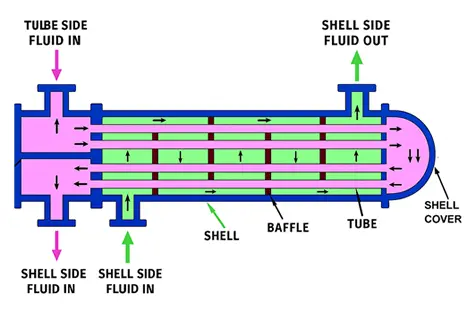

In a shell and tube heat exchanger, one fluid flows inside the tubes and the other fluid flows outside the tubes, within the shell. This setup allows efficient heat exchange between two fluids at different temperatures. The working principle of shell and tube heat exchanger is based on conduction and convection.

Benefits of Shell and Tube Heat Exchangers

- Highly efficient in transferring heat across large surface areas

- Built to handle extreme temperatures and pressure conditions

- Easy to keep and clean, with a straightforward construction

Key Advantages

- Modular design suitable for large plants

- Compatible with gas, liquid, steam and oil applications

- Durable and long-lasting performance

- Economical in terms of operation and maintenance

Applications of Shell and Tube Heat Exchangers

Shell and Tube Heat Exchangers are used in:

- Power generation plants

- Oil & gas refineries

- Chemical processing industries

- HVAC systems

- Units that process food and beverages

- Pharmaceutical manufacturing

Why Choose United Cooling Systems Pvt. Ltd.?

At

United Cooling Systems Pvt. Ltd., we are a trusted

shell and tube heat exchanger manufacturer in India, known for delivering

custom-built solutions to suit diverse industry needs. With a strong focus on

quality, design innovation, and timely service, we offer:

- Heat exchangers made in accordance with Indian, and ASME specifications

- Utilizing premium materials such as Inconel, CS, Cu, MS, SS, and MS

- Proven to deliver results in Indian industrial environments

- Professional assistance from conception to commissioning

Frequently Asked Questions

- Q1: What materials are used in Shell and Tube Heat Exchangers?

- A: We use stainless steel, carbon steel, copper alloys, and titanium, depending on the application.

- Q2: What is the difference between fixed and floating tube design?

- A: Fixed tubes are welded and rigid, while floating tube bundles allow for thermal expansion and easy cleaning.

- Q3: Can you customize heat exchangers for our plant?

- A: Yes, we offer tailor-made designs based on your temperature, pressure, and fluid requirements.

Conclusion

If you are looking for a

reliable and efficient heat transfer solution,

Shell and Tube Heat Exchangers from

United Cooling Systems Pvt. Ltd. are the right choice. With decades of experience and a strong presence in Indian industries, we ensure

performance, quality, and support that you can count on.

Get in Touch

Looking for the best shell and tube heat exchanger in India?

Call: +91 422 2670982

Email: enquiry@heatexchanger.co.in

Website: www.unitedcoolingtower.com